By Dave adkins & aaron leestma | isolation & actuation experts

The American Petroleum Institute (API) standard 598 provides industry standards for valve ratings and valve leakage. One of the testing requirements for the 598 standard is Closure Tests. Through these tests a leakage class can be assigned (I – VI) with the higher the value resulting in the least amount, or absence, of leakage.

The term zero-leakage is applied to certain valves that perform at the highest levels of these leakage classes. To achieve this level of shut-off in a valve typically comes down to the materials used in construction and the valve’s seating action (how the seal is made). Both the Vanessa Triple offset butterfly valve, and a rising stem ball valve are classified as zero-leakage valves. But there’s a catch…

There are different seating profiles such as mechanically forced, radial compression and camming action. While these seating technologies achieve a similar result with varying upfront costs, the ability to maintain zero leakage shutoff is directly related to seating style.

In this post, we'll look at these differences to better understand how this can affect long-term costs.

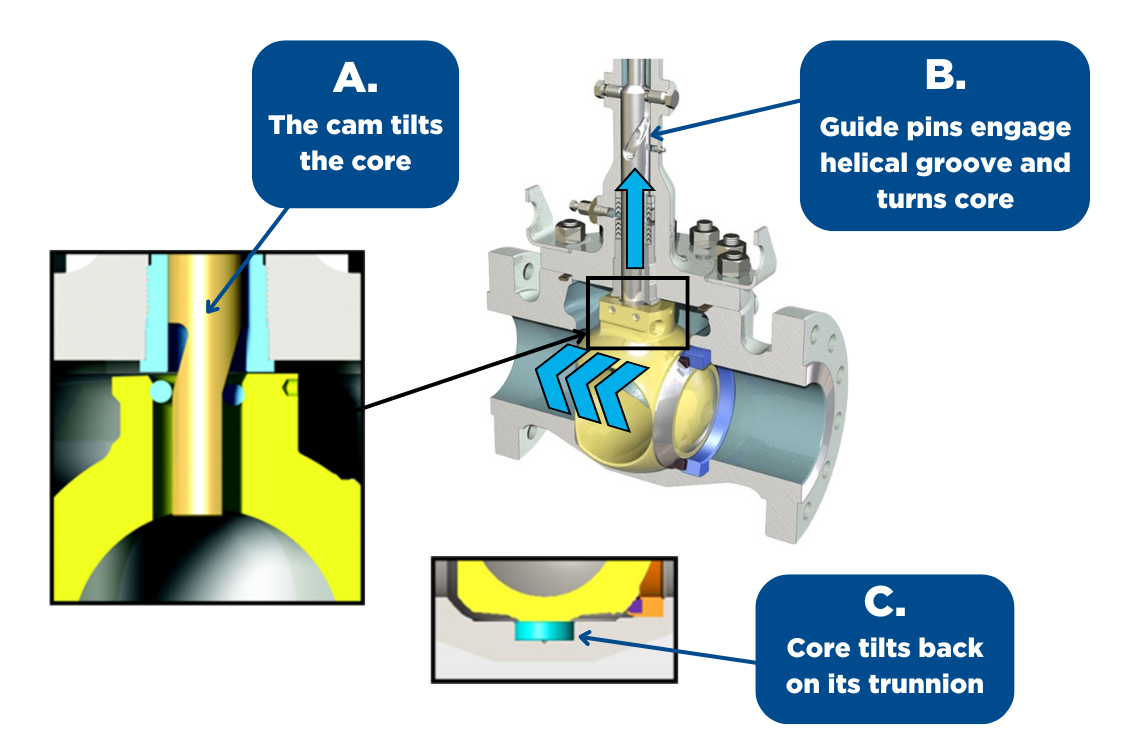

How a Rising Stem Ball Valve Works

Submit Your Questions

Issues & Hidden Costs with Rising Stem Ball Valves

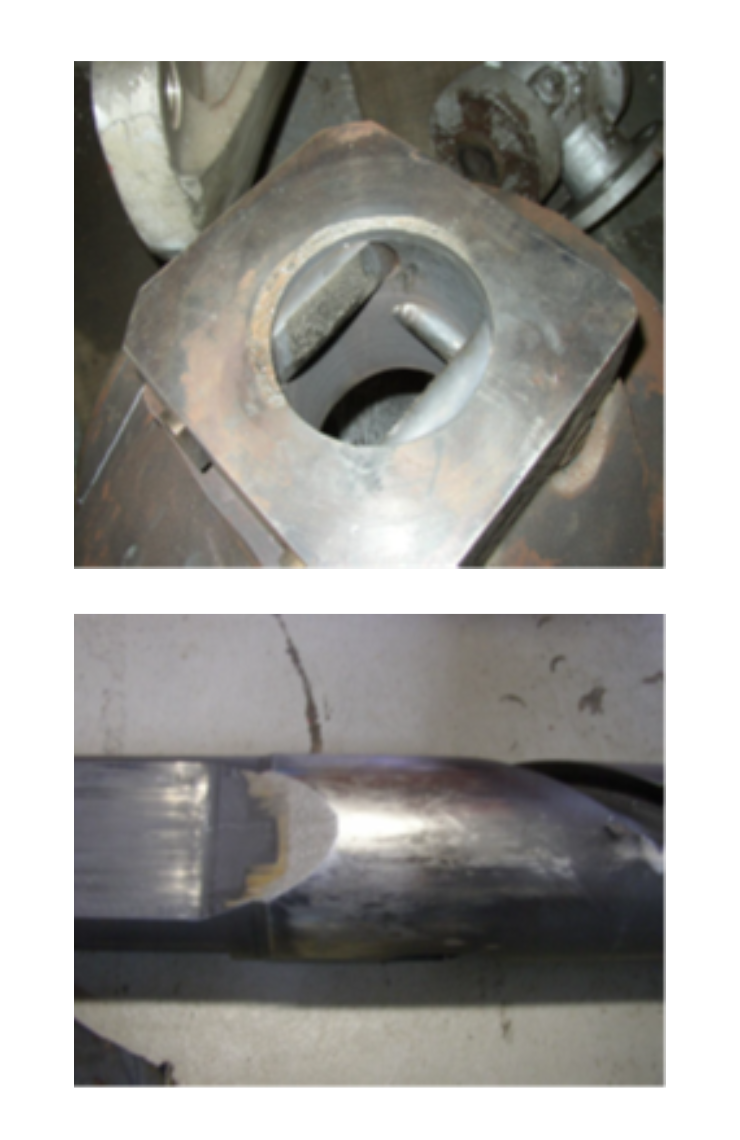

- Steam guides are a major wear and failure point

- Stem packing requires constant adjusting due to rising/linear stem operation

- Stem cam is a wear point for pushing the ball into the seat

- Seat wear is inevitable with soft seat spec'd valves

- Preventative maintenance schedule (3-4 year intervals)

- Repair requires specialty tooling and service personnel

- Parts are expensive and long lead time

- Linear valves require high thrust to operate resulting in larger (more expensive) actuators

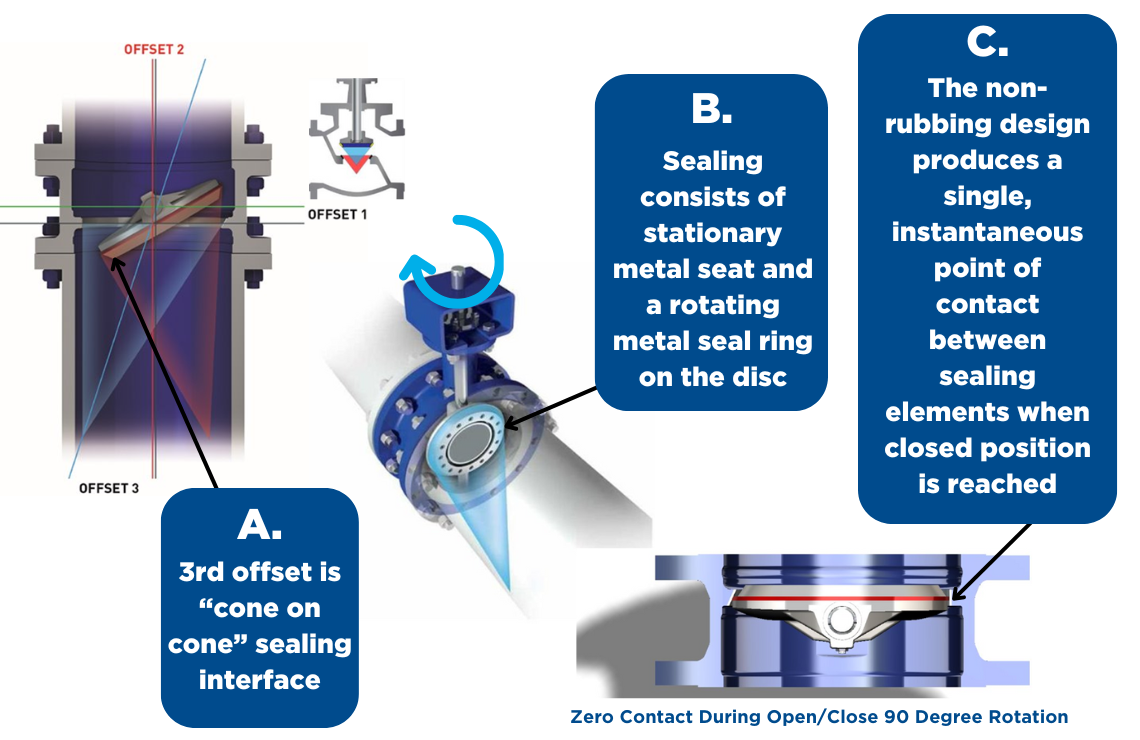

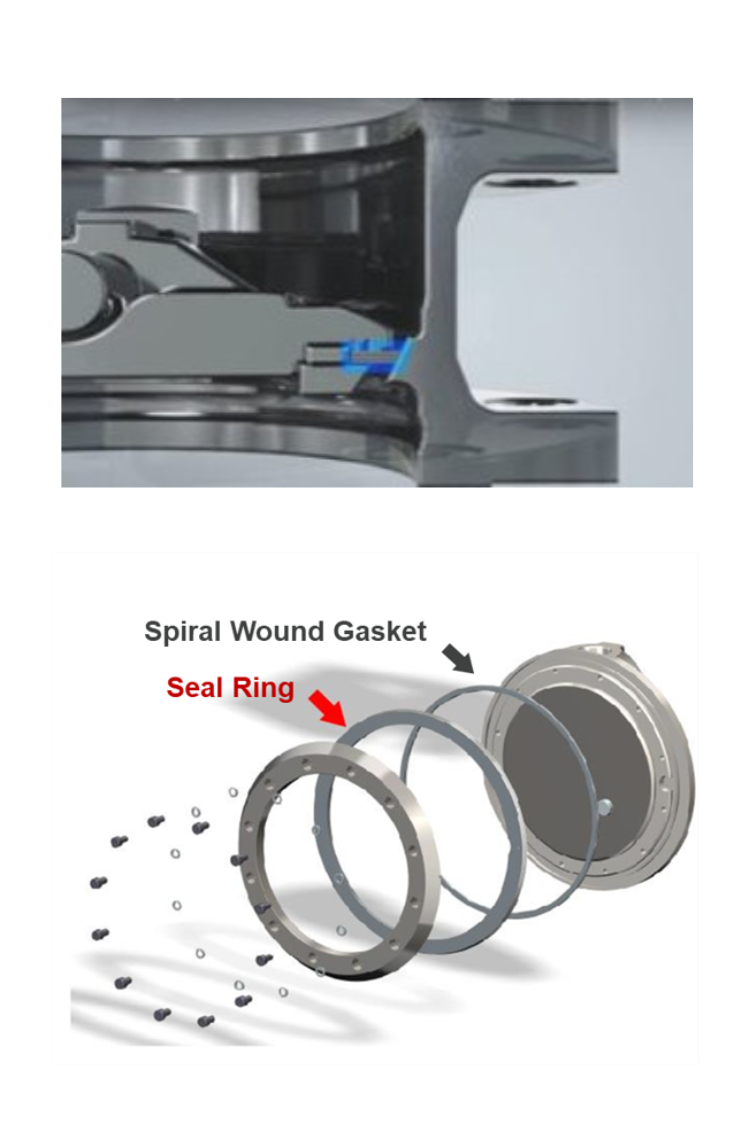

How a Vanessa Triple Offset Butterfly Valve Works

Low Costs with Vanessa Triple Offset Valves

- There is no rubbing or wearing on the seat or sealing surfaces

- Quarter-turn (instead of linear) packing technology reduces emissions over 99%

- Non-rubbing design results in extremely low torque requirements

- Virtually maintenance free

- Service intervals 10-25 or more

- Few parts and non-proprietary tools for maintenance

- Parts support from the US

- Low torque in a quarter-turn design - smaller standard actuation packages

The Bottom Line

When an application requires metal-seating, remember API code actually allows metal-seated valves to leak on day one. However, there are a few designs that can achieve bi-directional zero-leakage, even with metal seats. How these designs perform varies widely.

- Quarter-turn technology achieves lower emissions and smaller actuation:

- Quarter-turn valves only use 25% of the packing each stroke/operation.

- Linear valves use 100% of the packing every stroke/operation.

- Vanessa Triple-Offset Valves have a unique patented design that achieves bi-directional zero-leakage with no wear points.

- Rising stem ball valves have designed wear points that will require regular maintenance.

- With nearly 50 years of experience, Vanessa provides an improved alternative method to bi-directional zero-leakage metal-seated isolation valves.

Explore our proven, high-performance replacements designed to reduce maintenance and improve reliability.