Cyclonic has been setting the standard for precise and repeatable control of gases and liquids.

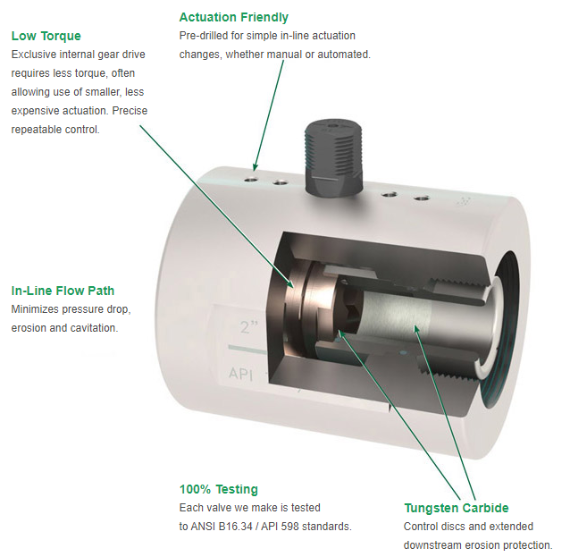

Like all Cyclonic valves, the TDC Series is built with the Cyclonic Design Difference. When you need to control a wide range of pressures and flow rates of gases or liquids, Cyclonic’s superior design gives you accurate control and a long safe valve life.

Exclusive Side-Entry Design:

The valve design allows for a simple, one-man changeout of the tungsten carbide discs to reconfigure the valve for changed flow conditions. Easily complete in-line inspection and maintenance critical for increasing safety and protecting the environment - all without taking the valve out of line, or removing the actuator.

Exclusive Side-Entry Design:

The valve design allows for a simple, one-man changeout of the tungsten carbide discs to reconfigure the valve for changed flow conditions. Easily complete in-line inspection and maintenance critical for increasing safety and protecting the environment - all without taking the valve out of line, or removing the actuator.